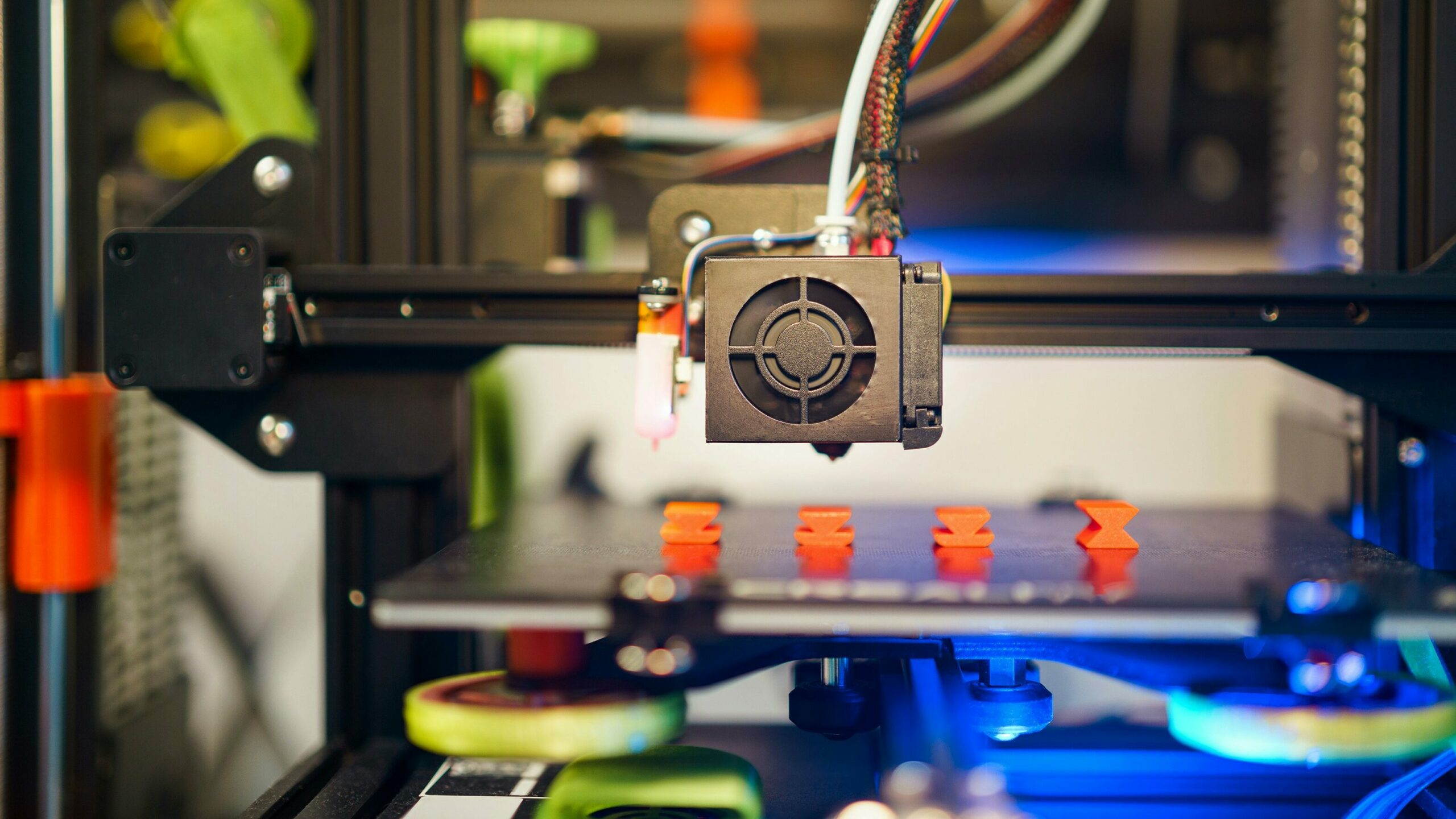

Navigating through all the purchases related to 3D printing can be challenging. But at Imprimy.com we’re here to guide you in your purchases so that you can make the best possible choices with our 3D printing buying guides.

What Are Our 3D Printing buying guides Tips ?

To choose the right 3D printer, you must first define your needs so that you know exactly what type of printer is best for you and which model to select based on a variety of criteria.

Selecting the Type of 3D Printer That Best Meets Your Needs

- FDM Printers (Fused Deposition Modeling):

These are among the most common types of 3D printers. Easy to use, they are accessible to beginners. The basic filaments used do not require special precautions, unlike other types of printers. If you’re starting out and wish to print relatively large objects without needing an air extraction system at home, FDM printers are a great choice. - SLA Printers (Stereolithography):

These printers use ultraviolet light to polymerize layers of resin. Resin, however, is toxic and requires special handling. You’ll need UV treatment equipment to cure your prints and methods to safely dispose of leftover liquid resin, as it cannot be poured down the drain. If you have the space for a complete setup and want to produce small, highly detailed objects like figurines, SLA printers are ideal. - SLS Printers (Selective Laser Sintering):

These printers solidify layers of metal, polymer, or ceramic powders using lasers. Primarily industrial and very expensive, SLS printers are not typically intended for personal use.

Criteria to Choose the Right 3D Printer Model

- Print Volume: Ensure the printer can handle the size of objects you wish to create. A larger print volume offers more versatility for future projects.

- Precision and Resolution: Higher precision produces higher-quality objects with appealing aesthetics.

- Print Speed: Faster printers can produce large quantities of objects within tight deadlines.

- Ease of Use: Opt for user-friendly models to save time on setup and calibration.

- Support and Community: A strong user community or brand support can provide valuable assistance and resources.

- Budget: Factor in initial purchase cost, material expenses, maintenance, and upgrades over time.

What Are Our Tips for Choosing Printing Materials?

Select 3D printing materials compatible with your printer and suited to your mechanical, aesthetic, or ecological needs.

Popular 3D Printing Materials

- PLA: Biodegradable and easy to use, PLA offers good surface quality and minimal warping but is less heat-resistant and durable than other plastics. Ideal for rapid prototyping, toys, and educational models.

- ABS: Robust and heat-resistant, ABS provides durability and flexibility but requires a heated print chamber due to its tendency to warp during printing. Suitable for mechanical parts and durable objects.

- PETG: Combines PLA’s ease of use with ABS’s durability. PETG resists chemicals and moisture but may encounter adhesion or stringing issues during printing. Perfect for functional parts and mechanical components.

- Nylon: Highly resistant, flexible, and durable, making it ideal for functional and mechanical parts. However, it is sensitive to moisture and can be challenging to print.

- TPU: A flexible, elastic filament with excellent wear and abrasion resistance, ideal for phone cases and soft components. TPU requires precise settings to avoid clogging.

- SLA Resins: Provide exceptional precision and detail, available in various properties such as hardness, flexibility, and biocompatibility. However, they are costly and require UV curing and strict safety measures.

Key Material Selection Criteria

- Compatibility with Your Printer: Ensure the material matches your printer’s extrusion temperature, heated bed, and filament type.

- Mechanical and Thermal Properties: Select materials with properties suited to your project (e.g., strength, flexibility, heat resistance).

- Ease of Printing: Consider materials that minimize warping and offer strong bed adhesion.

- Finishes and Post-Processing: Some materials allow for techniques like sanding, painting, or UV curing.

- Cost: Balance performance with affordability.

What Are Our Tips for Accessories and Spare Parts for 3D Printing?

To maintain and enhance your 3D printer’s performance, ensure that accessories and spare parts are compatible and tailored to your machine’s needs.

Essential Accessories for Quality Prints

- Heated Bed: Ensure compatibility with your printer and follow installation instructions for proper wiring and alignment.

- Leveling Sensor: Simplifies the leveling process for optimal first-layer adhesion.

- Filament Dryer: Removes moisture from filaments, improving print quality and reducing defects.

Crucial Spare Parts for Maintenance

- Nozzles: Keep spares in various sizes and materials to address clogging or adapt to different printing needs.

- Extruder Gears: Essential for filament extrusion, these may wear out over time.

- Motors: Have backups for axis movement and extrusion control.

- Belts and Bearings: Replace worn components to maintain precision and reduce noise.

Conclusion: Effective Management of 3D Printing Purchases

Efficiently managing your 3D printing purchases is crucial for optimizing quality and cost-efficiency. Proper planning ensures compatibility, reduces downtime, and helps you stay updated with technological advancements while maintaining environmentally responsible practices.

Picture by Jakub Żerdzicki from Unsplash

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.

Check our other contents about 3D printing purchases :

Request a 3D printing quote

Are you thinking of requesting a 3D printing quote but don’t exactly know what to…

Choosing a 3D printer: resin or filament?

You don’t know what to choose between a resin 3D printer and a filament 3D…

On-Demand 3D Printing

Do you want to discover everything you need to know about on-demand 3D printing? Imprimy…