Do you want to know everything about stringing that can appear on your 3D prints and how to effectively fix this defect? At Imprimy, we’re here to guide you toward achieving flawless 3D printing.

To avoid stringing in 3D printing, optimize your printer’s retraction settings, lower the extrusion temperature, and adjust the printing speed to minimize the unwanted strings between parts of the model.

What is stringing?

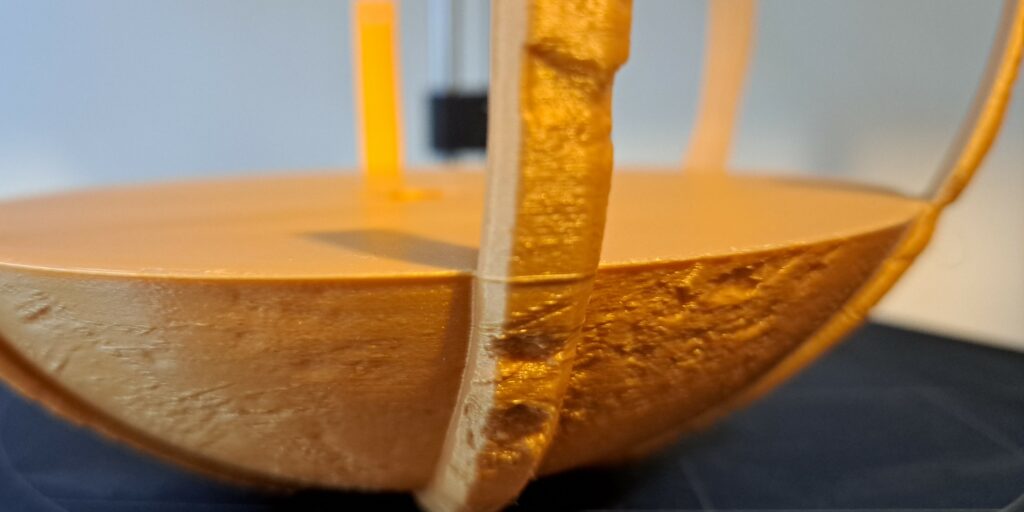

Stringing in 3D printing is a defect characterized by the appearance of thin strings or filaments between the different parts of your printed object. By performing a few tests, you can easily identify the cause of this issue and take steps to correct it, thereby improving the quality of your 3D prints.

- What is stringing?

- What are the technical causes of stringing?

- How to Prevent and Fix Stringing in Your 3D Prints?

- Which Materials and Types of Filament Can Influence Stringing?

- Which Tools and Tests to Use to Diagnose and Fix Your Stringing Issues?

- Conclusion: Stringing in Your 3D Printed Parts

- Our other contents about 3D printer maintenance :

Definition of Stringing in 3D Printing

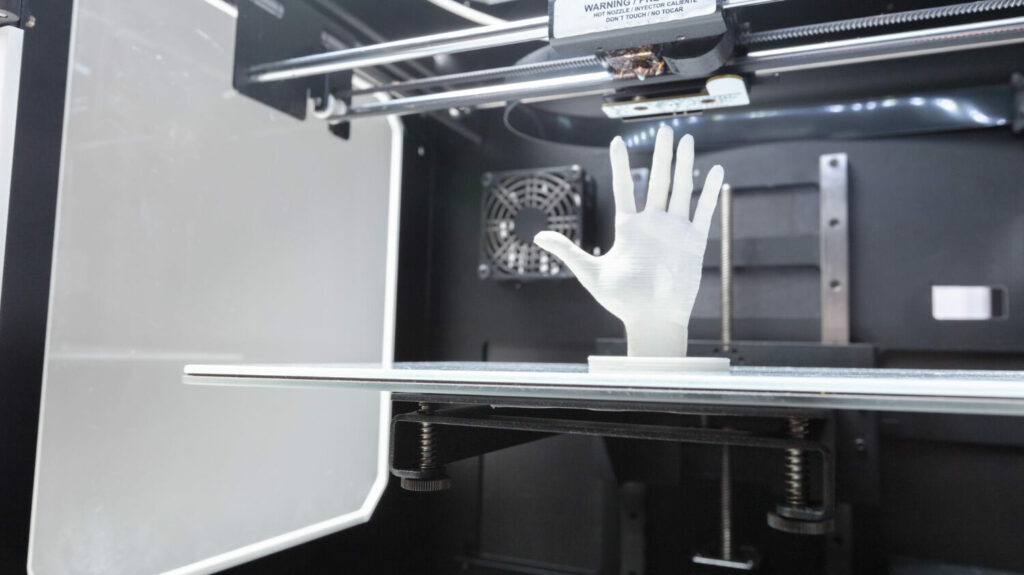

Stringing, also known as the “hairy effect,” is a common phenomenon in 3D printing. It is characterized by the appearance of thin plastic filaments between different parts of a 3D-printed object. Stringing mainly occurs when filament continues to ooze from the nozzle during travel moves—movements where no printing is supposed to happen—thus creating unwanted strings.

This issue is often related to improper settings for extrusion temperature, retraction, or the travel speed of your printer. Since stringing can affect the final appearance of a print, you can try several methods to minimize or eliminate it, which will help improve the overall quality of your 3D prints.

The main causes of stringing

The main causes of stringing in 3D printing are related to several technical factors such as:

- An extrusion temperature that is too high can make the filament too fluid, which encourages oozing during the movement of the print head.

- Improper retraction settings—the pullback of filament before a move—can also lead to material leakage.

- A travel speed that is too slow increases the risk of filament forming strings between different areas of the print.

- Moisture in the filament, especially if it has been improperly stored, can worsen this issue by altering its physical properties.

What are the technical causes of stringing?

Stringing in 3D printing is mainly caused by incorrect retraction settings, an extrusion temperature that is too high, an inappropriate print speed, or mechanical issues with the extruder.

An Overly High 3D Printing Temperature

A printing temperature that is too high can make the filament too liquid, causing it to ooze even when extrusion is paused. This leads to the formation of unwanted filaments that can connect different parts of a 3D-printed object.

Each filament type has an optimal temperature range, and exceeding this range increases the risk of stringing on your print.

Retraction settings

Retraction settings play a key role in preventing stringing. Retraction involves slightly pulling back the filament from the nozzle before it moves without printing, in order to limit material leakage.

If the retraction distance or retraction speed is not properly adjusted, the filament may continue to ooze, resulting in the formation of unwanted filaments on your 3D print.

Too little or too slow retraction is not enough to prevent this oozing, while excessive retraction can lead to under-extrusion.

You should therefore test and optimize these settings according to the type of filament you are using to achieve high-quality 3D prints.

Travel speed

The travel speed of the print head, when it moves without printing, has a direct impact on stringing. If this speed is too slow, the filament has more time to ooze from the nozzle, forming unwanted strings between different parts of the printed object.

By increasing the travel speed, you reduce the oozing time and, consequently, the risk of stringing. An optimal speed setting allows the print head to move quickly between non-printing areas while maintaining the quality of the print.

Filament Moisture

Moisture in the filament can significantly contribute to stringing. Filaments easily absorb moisture from the air, especially materials like PLA and nylon. When moist filament is heated in the nozzle, the trapped water vaporizes, creating bubbles and causing material leakage in the form of fine strings.

This phenomenon not only affects the quality of your 3D prints, but can also lead to other printing defects. To prevent this, you should ensure that your filaments are stored in a dry environment and dried if necessary before each use.

How to Prevent and Fix Stringing in Your 3D Prints?

To reduce the risk of stringing in your 3D prints, you should:

- Ensure proper storage of your filaments

- Adjust the printing temperature

- Optimize your retraction settings

- Increase the travel speed of the print head

Adjusting the Temperature

Adjusting the printing temperature is a key step to reduce stringing. If the temperature is too high, the filament becomes too fluid and tends to ooze, leading to the formation of unwanted strings.

To minimize this, you should gradually lower the extrusion temperature until you find the right balance. The temperature must be low enough to limit oozing, but high enough to ensure good adhesion and proper extrusion of the filament during printing.

Each filament has an optimal temperature range, and precise adjustments within these limits can significantly improve the quality of your 3D prints by reducing stringing.

Optimizing Retraction

Optimizing retraction is essential to prevent stringing. Retraction involves slightly pulling back the filament from the nozzle before a non-printing move, which reduces the risk of oozing. For effective optimization, it’s important to adjust both the retraction distance and the retraction speed.

A retraction distance that is too short won’t pull back enough filament, while a too long distance can cause under-extrusion problems. Similarly, a too slow retraction speed allows more time for the filament to ooze. Testing and adjusting these parameters, specific to each type of filament, can significantly improve print quality by greatly reducing stringing.

Increasing Travel Speed

Increasing the travel speed of the print head is an effective way to limit stringing. When the head moves without printing, a speed that is too slow allows the filament to ooze and form strings between printed parts. By increasing this speed, you reduce the oozing time, which decreases the formation of unwanted filaments.

However, it’s crucial to find a balance: a travel speed that is too fast can affect the accuracy of movements. Adjusting this parameter, often available in slicing software, contributes to cleaner prints with no stringing.

Storing and Managing Your Filaments

Properly storing and managing your filaments is crucial to avoid stringing. Filaments can absorb moisture from the air, which can cause unwanted oozing during printing. To prevent this, it is recommended to keep filaments in dry environments, ideally in airtight boxes with desiccant packets to maintain a low humidity level.

Additionally, before using filament that has been stored in humid conditions, it is often helpful to dry it using a filament dryer. Good storage and handling of filaments also helps reduce stringing and improve the quality of your 3D prints.

Which Materials and Types of Filament Can Influence Stringing?

Depending on the specific characteristics of the filaments you use for your 3D prints, you may experience more or less stringing on your final 3D print.

PLA Behavior Regarding Stringing

PLA (polylactic acid) is generally less prone to stringing compared to other materials, but it is not completely immune to this problem. PLA tends to produce less stringing due to its thermal properties, but if settings are incorrect, it can still suffer from it.

To minimize stringing with PLA, it is crucial to properly adjust the extrusion temperature, keeping it slightly below the recommended range, and to optimize retraction settings. By fine-tuning these parameters, you can take advantage of PLA’s properties to achieve cleaner prints and reduce unwanted strings.

ABS Behavior Regarding Stringing

ABS (acrylonitrile butadiene styrene) is more prone to stringing than some other materials due to its high extrusion temperature and melting properties.

ABS tends to ooze more easily, which can cause the formation of unwanted strings between printed areas. To reduce stringing with ABS, it is important to properly set the extrusion temperature within the recommended range, avoiding temperatures that are too high as they can encourage oozing.

Additionally, correctly adjusting retraction settings and increasing the travel speed of the print head can also help minimize stringing. Careful control of these parameters is essential to achieve clean prints with ABS.

PETG Behavior Regarding Stringing

PETG (glycol-modified polyethylene terephthalate) is particularly sensitive to stringing due to its high viscosity and melting properties. This material tends to ooze more, creating unwanted strings between printed parts.

To manage stringing with PETG, it is essential to adjust the extrusion temperature by lowering it slightly below the maximum recommended range to avoid excessive fluidity. Optimizing retraction settings is also crucial, as PETG may require more precise adjustments to prevent filament leakage.

Finally, increasing the travel speed of the print head helps reduce the time the filament can ooze and form strings. These adjustments allow better control of stringing and result in cleaner prints with PETG.

Which Tools and Tests to Use to Diagnose and Fix Your Stringing Issues?

Finally, to reduce the effects of stringing on your 3D prints, you should not hesitate to perform calibration tests and use software features that will help make your 3D prints cleaner and more precise.

Performing Calibration Tests

Performing calibration tests is essential to optimize printing parameters and reduce stringing. These tests allow you to precisely adjust factors such as extrusion temperature, retraction settings, and travel speed.

For example, you can print temperature towers to identify the optimal temperature for your filament, or retraction towers to determine the ideal retraction distance and speed to avoid filament leakage.

By conducting these tests, you can directly observe the impact of each setting on stringing and adjust parameters accordingly. This helps improve the quality of your prints by reducing filament-related defects.

Software Features

Slicing software features play a key role in managing stringing. Tools like “combing mode” in Cura help minimize non-print moves by guiding the print head along already printed areas, thus reducing the risk of string formation.

“Wipe” and “coasting” are other available options that help eliminate filament residue before and after moves, reducing oozing. By using these features, you can fine-tune printing parameters more precisely to limit stringing and improve the overall quality of your 3D printed parts.

Conclusion: Stringing in Your 3D Printed Parts

In conclusion, stringing is a common challenge in 3D printing that can degrade the quality of your printed parts by creating unwanted strings between printed areas. To effectively reduce it, it is crucial to adjust several parameters, including extrusion temperature, retraction settings, travel speed, and filament management.

Using advanced slicing software features and performing calibration tests will also help you fine-tune your settings and achieve cleaner results. By adopting these best practices, you can minimize stringing and improve the quality and precision of your 3D prints.

Picture : Imprimy.com

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.

Our other contents about 3D printer maintenance :

Nozzle friction : the nozzle of your 3D printer is rubbing

Do you want to know everything about the friction of your 3D printer’s nozzle on…

Ghosting in 3D printing

Do you want to learn everything there is to know about ghosting in 3D printing?…

What is layer shifting in 3D printing?

Do you want to know everything about layer shifting and the actions to take to…