Do you want to learn everything there is to know about ghosting in 3D printing? At Imprimy, we are here to explain this issue that can affect your 3D prints.

What is ghosting?

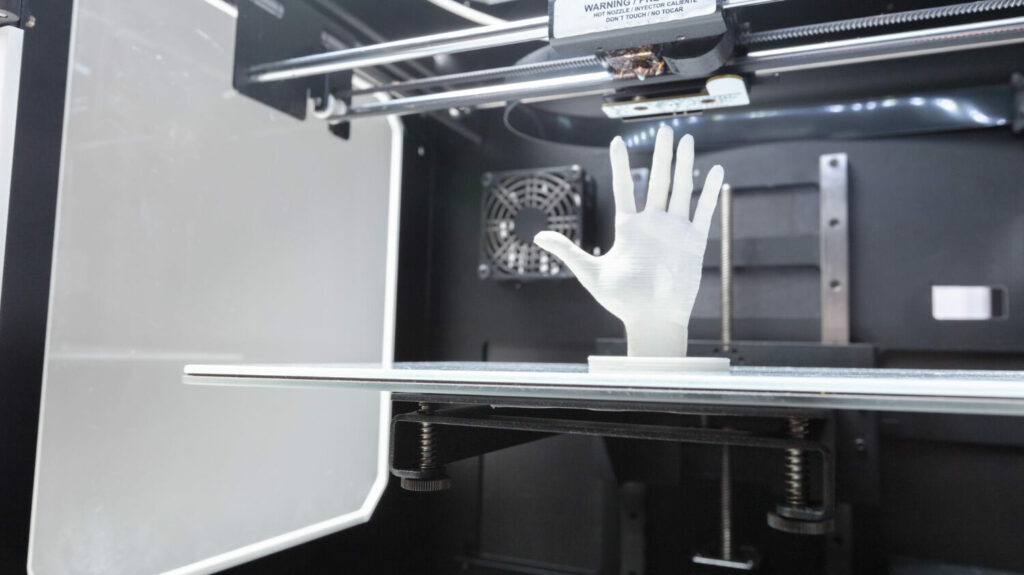

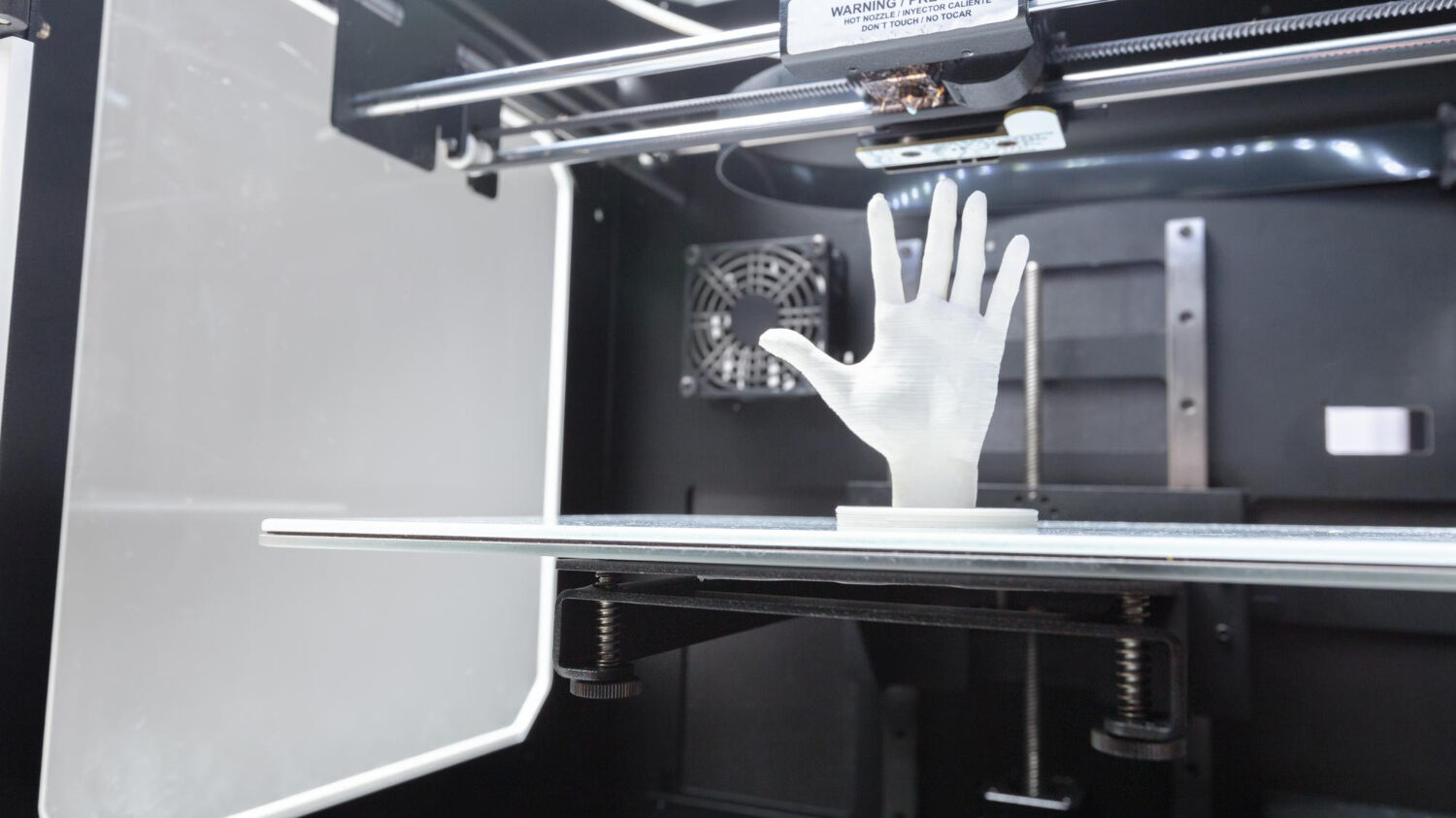

Ghosting is a 3D printing defect that affects the objects being printed by creating visual duplicates, which tarnish the final quality of your print.

A detailed description of ghosting

Ghosting in 3D printing refers to the appearance of faint, shadow-like patterns or outlines on the surface of a printed object. These patterns are typically seen along the edges or contours and resemble echoes of the printed layers. Ghosting is caused by vibrations or sudden movements of the printer’s components, particularly the print head or extruder, during the printing process.

When these vibrations occur, they cause the print head to deviate slightly from its intended path, resulting in inaccuracies that leave behind unwanted visual artifacts. The effect can be more pronounced when the printing speed is high, or if the printer is not properly calibrated. The presence of ghosting diminishes the overall quality of the print, creating a blurry or less precise finish.

To prevent ghosting, it is essential to minimize vibrations, use appropriate print speeds, and ensure the printer’s components are properly calibrated and stabilized.

The manifestation of ghosting on your printed objects

Ghosting typically appears as repetitive patterns on the surface of a 3D printed object, especially along the edges or contours. These “echoes” are usually visible as blurry or jagged lines that mimic the shape of the printed layers. The effect is more noticeable on curved or complex surfaces, where the repetitive nature of ghosting can distort the appearance of the model.

You may notice ghosting when viewing your print from certain angles or under specific lighting conditions, as the shadow-like patterns become more visible. These artifacts can also be found in layers that follow the primary print path, giving the object an uneven or “washed-out” look.

The manifestation of ghosting generally compromises the smoothness and precision of the surface, negatively affecting the overall aesthetic and detail of the printed object.

What are the causes of ghosting?

The causes of ghosting can be mechanical, related to improper 3D printing settings, or even due to an unsuitable material.

Ghosting caused by mechanical issues

Mechanical causes of ghosting typically arise from vibrations or instability in the 3D printer’s components. These vibrations can disrupt the precision of the printing process and result in visual artifacts on your prints. Here are some common mechanical factors that contribute to ghosting:

- Printer Vibrations: If the printer’s moving parts, such as the print head or the gantry, experience vibrations during movement, they can leave behind unwanted patterns on the print surface. Vibrations may occur due to a loose frame, imbalanced parts, or high-speed movements.

- Loose Components: If parts such as belts, screws, or the print bed are not securely tightened, they can cause wobbling during printing. This instability can lead to slight misalignments in the print head’s movement, which in turn causes ghosting on the surface of the object.

- Weak Printer Frame: A printer with a weak or flexible frame will not be able to absorb the movements and stresses involved in the printing process. This instability can cause slight shifts in the print head, which result in ringing or echoing patterns on the printed object.

To mitigate ghosting caused by mechanical issues, it’s essential to ensure that your printer is well-assembled, all components are tight and secure, and the frame is stable. Additionally, reducing print speed and ensuring smooth, precise movements will help minimize vibrations and improve print quality.

Ghosting caused by incorrect printing settings

Improper 3D printing settings can significantly contribute to ghosting. When settings such as print speed, acceleration, and jerk are not properly adjusted, they can lead to vibrations and inaccurate movements of the printer head, resulting in visual defects on your print. Here are the key parameters that can cause ghosting:

- High Print Speed: Printing at too high a speed can cause the printer head to move too quickly, making it harder for the machine to maintain precise control. This can lead to unwanted vibrations, which manifest as ghosting on the printed object.

- Excessive Acceleration: Acceleration determines how quickly the printer head changes direction. High acceleration can cause sudden movements that create additional vibrations, leading to ghosting. Lowering the acceleration can help to achieve smoother and more stable movements.

- Incorrect Jerk Settings: Jerk defines the instantaneous change in movement direction. If jerk settings are too high, the printer may suddenly change direction, causing vibrations that disrupt the print and result in ghosting patterns. Reducing jerk values helps to avoid these abrupt movements.

- Insufficient Layer Height or Nozzle Width Adjustments: Incorrect settings for layer height or nozzle width can lead to uneven material deposition, which might worsen the effects of ghosting.

To reduce ghosting caused by poor settings, it’s crucial to adjust print speed, acceleration, and jerk values for smoother movements. Slower speeds, optimized acceleration, and proper jerk settings will help minimize vibrations and improve the overall quality of the print.

Ghosting caused by materials

The type of material used in 3D printing can significantly contribute to ghosting, especially if the material has characteristics that amplify vibrations or cause the printer to move imprecisely. Here are some material-related causes of ghosting:

- Flexible Filaments: Materials like TPU (Thermoplastic Polyurethane) or other flexible filaments are more prone to ghosting because their elasticity can cause the filament to bend and create more resistance during extrusion. This results in uneven printing and vibrations that can leave ghosting patterns on the print.

- Low-Quality Filament: Low-quality filaments can contain impurities or inconsistent diameters, which affect extrusion and flow consistency. This can cause jerky or irregular printing behavior, leading to ghosting effects.

- Heavy Materials: Some dense filaments, such as filled materials (e.g., metal-infused filaments), can add extra weight to the print head or extruder, making it harder for the printer to maintain precise movements. This added weight can result in slower, less accurate printing that can lead to ghosting.

- Incorrect Material Settings: If the printer settings, such as temperature or flow rate, are not calibrated correctly for the chosen material, it can lead to issues like over-extrusion or under-extrusion. This can cause inconsistencies in layer formation, contributing to the manifestation of ghosting.

To avoid ghosting caused by materials, it is essential to use high-quality filaments that are compatible with your printer and to adjust your settings based on the material’s specific requirements. Using rigid, stable filaments and ensuring proper material handling will help minimize ghosting and produce cleaner prints.

How to identify the symptoms of ghosting ?

Ghosting in 3D printing can be recognized by certain visual signs, which you will need to differentiate from other issues that may affect your prints.

The visual signs of ghosting

The visual signs of ghosting on your 3D prints:

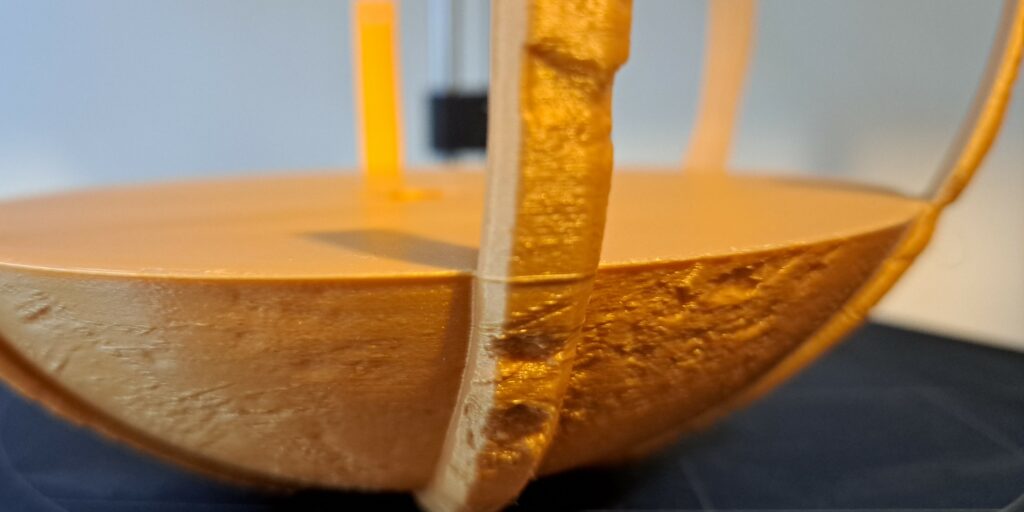

- Repetitive Rings or Echoes: One of the most common signs of ghosting is the appearance of faint, repeating rings or echo-like patterns along the contours of the object, particularly around edges or corners. These patterns usually follow the shape of the model and are offset from the primary print lines.

- Jagged or Blurry Edges: Ghosting can cause the edges of the print to appear blurry, jagged, or less defined. Instead of clean, sharp lines, you may notice irregularities or distortions along the object’s perimeter.

- Uneven Surface Texture: Areas affected by ghosting may exhibit uneven textures, with some regions appearing smoother while others show slight ripples or distortions. This is often due to vibrations affecting layer deposition.

- Lines on Curved or Sloped Surfaces: Ghosting is especially visible on curved or sloped surfaces, where faint lines or rings may form. These lines can create a “wavy” look on otherwise smooth areas of the print.

- Shadows or Stray Lines: Ghosting can also cause faint shadow-like lines to appear on the surface, particularly near sharp corners or abrupt direction changes during printing. These lines may seem to “bleed” from one area to another, resembling a fading echo.

By carefully observing these visual signs, you can identify ghosting on your prints and address the underlying causes, whether they involve printer settings, material issues, or mechanical problems.

The differences between ghosting and other defects

The differences between ghosting and other 3D printing defects lie in their visual manifestations and specific causes. Ghosting is characterized by blurry contours and “ghost” lines that seem to follow the movements of the printhead, giving the impression of duplication along the edges and flat surfaces. In contrast, under-extrusion results in a lack of material in certain areas, creating incomplete or rough surfaces, while over-extrusion leads to excessive filament blobs along the edges.

Other defects, such as warping, manifest as lifted corners of the prints due to thermal stresses, whereas stringing is seen as filament threads between parts of a model, caused by poor retraction. Layer lines or streaks, on the other hand, can be caused by poor nozzle calibration or variations in filament quality, which differ from the resonance effects associated with ghosting. Thus, although these defects share some common traits, their specific causes and appearances require distinct approaches to be corrected.

What are the solutions to reduce ghosting?

Different solutions, ranging from mechanical and technical adjustments to the choice of material used for your prints, can help you eliminate ghosting issues.

Mechanical adjustments to make

- Stabilize the Printer: Place your printer on a solid, flat surface to minimize vibrations. An unstable surface can cause your printer to shake, leading to ghosting. Using vibration-damping mats or placing the printer on a sturdy table can help improve stability.

- Tighten Loose Parts: Check for any loose components in your printer, especially in the frame, the extruder, and the print bed. Loose parts can contribute to unnecessary movement during printing, exacerbating ghosting. Tightening these parts ensures smoother operation.

- Upgrade to a Sturdier Frame: If you’re using a printer with a flimsy or less rigid frame, consider upgrading to a more robust machine or reinforce your current frame. A stiffer frame reduces the chances of mechanical flex, which can lead to unwanted vibrations that cause ghosting.

- Install Anti-Vibration Mounts: Adding dampers or anti-vibration mounts to the motors or the printer’s frame can absorb unwanted vibrations. These accessories can significantly reduce the occurrence of ghosting, especially in printers that may have a more flexible design.

- Check the Belts and Pulleys: Ensure that the belts on your printer are tight and properly calibrated. Loose or worn belts can cause uneven movement, leading to artifacts like ghosting. Regularly check the tension and replace any worn-out belts for optimal performance.

- Improve the Z-Axis Stability: The Z-axis is especially prone to wobbling and vibrations. Ensure that the Z-axis leadscrew is properly lubricated and aligned. If there is wobbling, it can cause uneven layer stacking, contributing to ghosting.

By making these mechanical adjustments, you’ll help minimize vibrations and ensure that your 3D printer operates more smoothly, ultimately reducing the likelihood of ghosting in your prints.

Reinforcing the Printer’s Structure

Reinforcing the 3D printer’s structure is a crucial step in minimizing ghosting and improving overall print quality. To begin, it is recommended to add additional supports or reinforcements to the printer’s frame, which helps reduce vibrations during the rapid movements of the printhead.

Using durable materials such as aluminum or steel for the frame construction can also contribute to better stability. Additionally, adding rubber feet or anti-vibration pads can help absorb shocks and decrease oscillations, especially if the printer is placed on an unstable surface.

Checking and Tightening Certain Parts

Checking and tightening certain parts of your 3D printer are crucial steps to prevent ghosting and ensure high-quality prints. Start by carefully inspecting all screws, bolts, and nuts, making sure they are properly tightened, as loose parts can cause vibrations and imprecise movements of the print head. It’s also important to check the belts on the X and Y axes: they should be adequately tensioned, as loose belts can cause oscillations and misalignments during movement.

Don’t forget to check the stepper motor assemblies, as well as the bearings and rails, as their proper condition also contributes to the stability of the printer. By regularly performing these checks and tightening the necessary parts, you minimize the risks of ghosting and ensure optimal performance of your machine, resulting in sharper and more precise prints.

The reduction of printing speed

Optimizing some of your printing settings is essential to reduce ghosting and improve the quality of your 3D prints. To start, it is recommended to lower the printing speed, as high speeds can cause excessive vibrations during fast movements of the print head, resulting in blur effects. You should also adjust the acceleration and deceleration settings: values that are too high can cause jerky movements, while smoother acceleration helps stabilize motion and reduce resonances.

Additionally, it is important to pay attention to the extrusion temperature: an improper temperature can affect the filament’s fluidity, leading to poor adhesion and artifacts. Finally, perform print tests to fine-tune these settings based on the material used, as each filament has specific characteristics that can influence print quality. By optimizing these settings, you can minimize ghosting and achieve sharper, more professional results.

The adjustment of acceleration and deceleration settings

Adjusting the acceleration and deceleration settings is a crucial step in reducing ghosting and improving the print quality of your 3D printer. Excessive acceleration can cause jerky movements of the print head, leading to vibrations and oscillations that result in visible defects on your printed objects. By reducing the acceleration, you allow the printer to make smoother movements, which decreases the risk of resonance and improves detail accuracy.

Similarly, an overly aggressive deceleration setting can also cause shocks when the print head stops, leading to unwanted shifts. By adjusting the deceleration to be more gradual, you promote a smoother stop, helping to maintain print quality, especially on corners and fine details. To optimize these settings, it is recommended to perform several print tests by gradually modifying the acceleration and deceleration values until you find the optimal balance that minimizes ghosting while maintaining an acceptable print speed.

The choice of materials

The choice of materials is a crucial factor in reducing ghosting and ensuring high-quality 3D prints. Certain filaments, such as ABS or PETG, may be more prone to generating ghosting effects, especially when printed at high speeds, due to their viscosity and extrusion behavior. Therefore, opting for materials designed to minimize this phenomenon, such as PLA, which has better fluidity at lower printing temperatures, can help achieve sharper results.

Additionally, the quality of the filament plays an essential role: poor-quality or poorly stored filaments can contain impurities or have absorbed moisture, which can affect extrusion and cause visible irregularities in the prints. By choosing high-quality materials suited to your printer and specific projects, you reduce the risks of ghosting and enhance the aesthetics and precision of your printed objects. Be sure to consult the manufacturer’s recommendations for optimal printing settings for each type of material to maximize your 3D printer’s performance.

What tools and software can be used to diagnose ghosting?

You can use certain tools or test models to detect the source of your ghosting issues.

Existing diagnostic tools

Diagnostic tools related to 3D printing are essential for identifying and solving problems, including ghosting, and improving the quality of your prints. Among the most commonly used tools are slicing software, which allows you to analyze and visualize the print head’s paths, providing valuable insights into printing parameters and machine movements.

Additionally, vibration sensors can be installed to detect excessive oscillations and vibrations during printing, providing real-time data on the printer’s stability. Printers equipped with surveillance cameras can also be useful for observing the printing process and detecting visual anomalies.

Finally, forums and online communities dedicated to 3D printing are an excellent resource for sharing experiences and solutions, allowing users to get advice on diagnostic tools suited to their specific needs. By combining these different tools and approaches, you will be better equipped to diagnose and fix printing issues, including ghosting.

The importance of using test models to assess the quality of your 3D prints

The importance of using test models to assess the quality of your 3D prints cannot be overstated, as these models play a crucial role in diagnosing potential issues, such as ghosting, and optimizing print settings. By printing specific test models, such as calibration cubes, bridges, or parts with fine details, you can observe and analyze different aspects of the print, such as layer adhesion, dimensional accuracy, detail sharpness, and surface quality. These tests also allow you to quickly identify defects related to speed, acceleration, or filament quality, making it easier to make targeted adjustments to print settings.

Additionally, using test models helps compare results between different materials or settings, which can guide you in choosing the best configurations for your specific projects. By regularly incorporating test model prints into your routine, you will be able to continuously optimize your printing processes, ensure consistent quality, and reduce the risk of undesirable defects, while improving your skills and understanding of 3D printing techniques.

Conclusion: Ghosting in 3D Printing

In conclusion, ghosting in 3D printing is a complex phenomenon that can seriously affect the quality of your printed objects, but it is largely avoidable with a deep understanding of its causes and proper preventive measures. By identifying the visual signs of ghosting and distinguishing this defect from other printing issues, you will be better prepared to address potential problems.

Mechanical adjustments, optimizing print settings, choosing the right materials, and using test models are all essential strategies to minimize this phenomenon. By incorporating these best practices into your printing process, you will not only improve the quality of your creations but also enjoy a more satisfying and efficient printing experience. By paying attention to the details and adapting your techniques, you will be able to produce high-quality 3D prints that meet both your expectations and the needs of your projects.

Picture by fabrikasimf from Freepik. .

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.

Our other contents about 3D printer’s maintenance:

Nozzle friction : the nozzle of your 3D printer is rubbing

Do you want to know everything about the friction of your 3D printer’s nozzle on…

Ghosting in 3D printing

Do you want to learn everything there is to know about ghosting in 3D printing?…

What is layer shifting in 3D printing?

Do you want to know everything about layer shifting and the actions to take to…