Do you want to know everything about layer shifting and the actions to take to resolve these issues? We are here at Imprimy.com to answer all your questions about layer shifting in 3D printing.

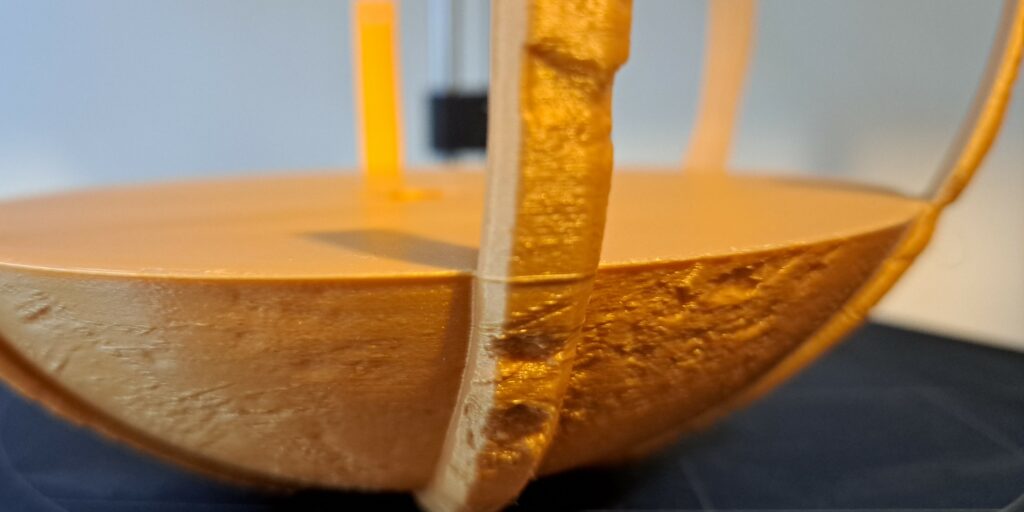

Layer shifting in 3D printing is when the printed layers misalign during the build process, causing the object to look distorted or crooked. It happens because the printer’s movement system loses its correct positioning. This results in visible offsets between layers and reduces print accuracy.

What is layer shifting in 3D printing?

Layer shifting in 3D printing is a defect where layers of material become misaligned during printing. This causes the layers to stack unevenly, resulting in visible shifts or offsets in the final object. It affects the overall accuracy and quality of the print.

The detailed definition of layer shifting:

Layer shifting is a printing issue where the layers of a 3D print misalign during the process. This causes the printed object to have offset layers, resulting in a distorted or skewed appearance. It often occurs due to mechanical problems like loose belts, stepper motor issues, or sudden printer movements.

The visible symptoms of layer shifting

The visible symptoms of layer shifting include misaligned layers that create a noticeable step or offset in the print’s surface. The print may look crooked or have jagged edges instead of smooth, straight lines. These defects often cause the overall shape to appear distorted or skewed.

What are the main causes of layer shifting?

The main causes of layer shifting are mechanical issues such as loose belts, worn-out gears, or stepper motor skips. Sudden printer movements or collisions can also cause the layers to misalign. Additionally, electrical problems like insufficient current to motors or firmware glitches may contribute to layer shifting.

How to avoid layer shifting?

To avoid layer shifting, ensure all belts and pulleys are properly tightened and in good condition. Regularly check the stepper motors and wiring to prevent skipped steps or electrical issues. Also, avoid sudden printer movements or collisions during printing to maintain accurate layer alignment.

What are the solutions to fix a layer shifting problem?

To fix layer shifting, first tighten or replace loose belts and pulleys to improve mechanical stability. Check and calibrate the stepper motors and drivers to prevent skipped steps. Additionally, update firmware and ensure the printer’s movement is smooth and free from obstructions or sudden jolts.

Conclusion: Layer Shifting in 3D Printing

Layer shifting in 3D printing is a common issue caused by mechanical or electrical problems that lead to misaligned layers. It negatively impacts the print quality by creating visible offsets and distortions.

Preventing and fixing it requires careful maintenance, proper calibration, and smooth printer operation.

Picture : Imprimy.com

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.