Do you want to discover everything you need to know about on-demand 3D printing? Imprimy is here to provide you with all the answers you’re looking for.

On-demand 3D printing allows users to order customized parts made according to their specifications, offering great flexibility and speed in the production of prototypes or finished products.

What is on-demand 3D printing?

On-demand 3D printing is a service offered by certain companies or organizations to make 3D printing accessible to all individuals or specific industry sectors.

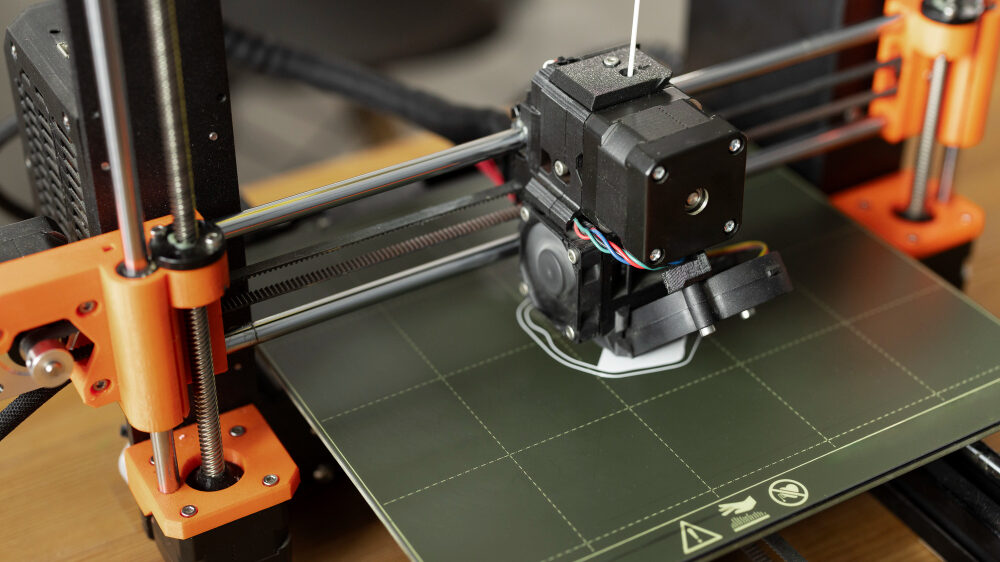

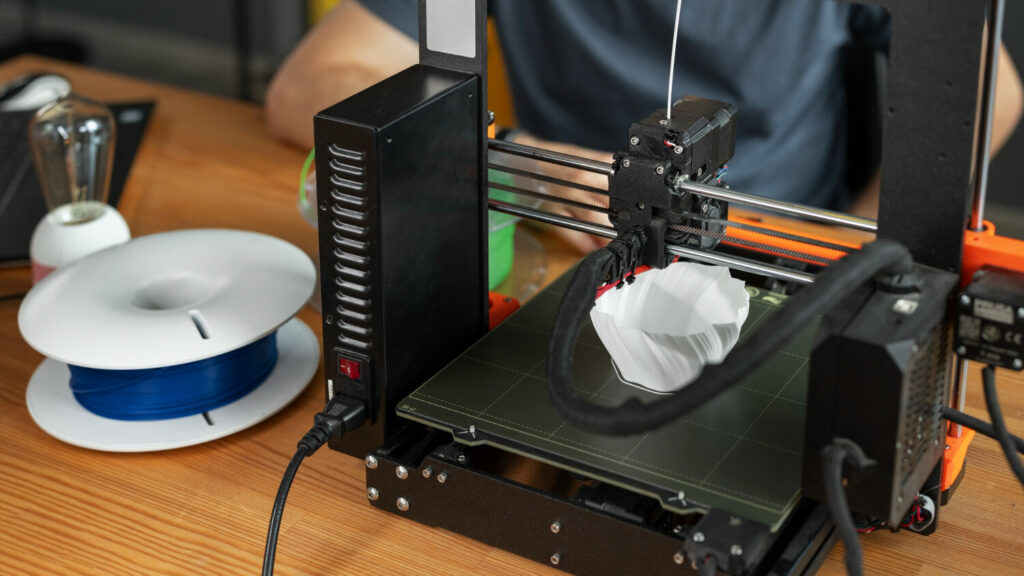

Reminders About 3D Printing

3D printing, also called additive manufacturing, is a revolutionary technology that allows you to create three-dimensional objects from digital models. Unlike traditional manufacturing methods, which often involve removing material or assembling parts, 3D printing lets you build objects layer by layer using various materials such as plastic, resin, metal, or even advanced composites.

This process offers you unprecedented flexibility, making it possible to create complex shapes, rapid prototypes, and custom parts with remarkable precision. Whether for industrial, medical, or creative applications, this technology helps you redefine production limits and is becoming increasingly integrated into everyday life.

On-Demand 3D Printing Services

On-demand 3D printing services give you the ability to design or customize objects without needing to own a 3D printer or have advanced technical skills. These specialized platforms let you upload a digital model, choose materials and finishes, then receive your final product directly at your home.

Additionally, many local workshops also offer this service, often with personalized advice. This service model is based on flexibility and accessibility: it is ideal for individuals wanting to carry out creative projects, but also for businesses looking to produce prototypes, spare parts, or small-batch products.

Sectors involved in on-demand 3D printing

On-demand 3D printing is suited to a wide range of sectors, radically transforming production methods.

- In industry, it’s used to design rapid prototypes, specific tooling, or custom spare parts, thereby reducing time and costs.

- The medical sector benefits from this technology to create custom prostheses, tailored implants, or even anatomical models to prepare for surgical interventions.

- In architecture and design, 3D printing enables the creation of complex models and unique decorative objects.

- The fashion and jewelry fields encourage innovation through avant-garde and custom creations.

- The aerospace and automotive industries use this technology to manufacture lightweight and durable parts, essential for improving performance while optimizing resources.

Thanks to its versatility, on-demand 3D printing has become an essential solution across many diverse sectors.

3D printing also allows individuals to easily create personalized objects at home, offering design freedom and accessible innovation for all.

Why Order On-Demand 3D Printing?

Ordering on-demand 3D prints allows you to customize your orders, reduce printing costs, and lower your ecological impact within your consumption habits.

Customization and Flexibility of On-Demand 3D Printing

On-demand 3D printing excels in its ability to offer unmatched customization. Unlike traditional production methods, it allows the creation of objects fully adapted to the needs or preferences of your users, whether it’s specific dimensions, complex shapes, or unique designs.

This approach is especially valuable in fields like medicine, where custom prostheses and implants greatly improve comfort and effectiveness for each patient. At the same time, companies can quickly adjust prototypes or products without heavy tooling investments.

With a wide choice of materials, colors, and finishes, on-demand 3D printing suits both creative projects for individuals and the technical requirements of professionals, offering responsiveness and creative freedom previously inaccessible.

Cost and time reduction in on-demand 3D printing

On-demand 3D printing stands out for its ability to significantly reduce costs and production times. Unlike traditional methods that often require expensive molds or tools, additive manufacturing allows you to produce your final model directly from a digital file, eliminating all intermediate steps.

This results in substantial savings, especially for small batches or prototypes. In terms of time, the speed of the process is a major advantage: an object can be designed, printed, and delivered within just a few days, whereas traditional processes may take several weeks.

Furthermore, by reducing the need for storage and enabling local or on-demand manufacturing, this technology limits logistics costs while optimizing resources, making your production more agile and competitive.

Environmental Impact of On-Demand 3D Printing

On-demand 3D printing presents mixed environmental impacts, but overall shows promise for more sustainable production.

On one hand, this process generates less waste than traditional methods, as it uses only the amount of material needed for each object. Additionally, by promoting local and on-demand production, it reduces the carbon footprint related to transport and storage of mass-produced goods.

However, some challenges remain: the materials used, such as plastics and resins, often come from non-renewable resources and can be difficult to recycle. This raises concerns about waste management and long-term impact.

Despite these limitations, advances are emerging, including the use of biodegradable or recycled materials, as well as the development of processes favoring a circular economy.

What are the limitations of on-demand 3D printing?

On-demand 3D printing has some limitations, such as cost and accessibility, certain technical constraints, and issues related to intellectual property protection.

Costs and Accessibility of On-Demand 3D Printing

The costs and accessibility of on-demand 3D printing vary depending on the materials, technologies used, and the complexity of the projects. While this technology is becoming increasingly affordable, especially for simple or small objects, prices can quickly rise for complex parts or those made from high-end materials like metal or specialized composites.

Moreover, although online platforms make access to these services easier, advanced 3D printers and certain processes remain expensive for individuals or small businesses. This still limits their widespread adoption in some contexts.

However, with the gradual decrease in printer and material prices, as well as the emergence of local and collaborative workshops, on-demand 3D printing is becoming more accessible, both for individuals and professionals wanting to use this technology without heavy investment.

Technical limitations of on-demand 3D printing

On-demand 3D printing, despite its many advantages, still presents several technical limitations.

First, printing speed remains a challenge: large or complex objects often require several hours or even days to produce.

Next, the range of available materials, though constantly expanding, remains limited compared to traditional processes, which restricts the mechanical or thermal properties of the manufactured parts.

Additionally, the precision and finish of certain objects may require post-processing steps, such as sanding or polishing, adding time and costs to the process.

Finally, the size of printers imposes constraints on the dimensions of the parts, sometimes requiring the assembly of multiple elements, which can weaken the structure. These limitations, while significant, tend to decrease thanks to technological advances, paving the way for even better performance in the coming years.

Intellectual property and regulations applied to on-demand 3D printing

Intellectual property and regulatory issues are major challenges for on-demand 3D printing due to the ease with which physical objects can be replicated.

Indeed, the digitization and sharing of 3D files pose increased risks of counterfeiting or unauthorized use of designs protected by copyrights, patents, or trademarks.

Creators and companies must therefore be extra vigilant to protect their works and innovations, but existing legal frameworks struggle to keep pace with this rapidly evolving technology.

Moreover, the manufacturing of sensitive objects, such as firearms or security equipment, raises important regulatory and liability questions. Some countries have begun to impose restrictions on the creation and distribution of certain digital files or printed objects, but these rules remain fragmented globally.

Thus, to develop on-demand 3D printing in an ethical and secure manner, a balance must be found between innovation, rights protection, and the implementation of appropriate regulations.

What are the future prospects for on-demand 3D printing?

The development of 3D printing enables access to technological advancements and unprecedented economic opportunities for individuals.

Technological advances of companies offering on-demand 3D printing

Companies offering on-demand 3D printing have made significant technological advances, especially in materials and speed. They have expanded their material range to include more robust options like metal, reinforced composites, and biodegradable plastics, enabling the production of durable and resistant parts.

The 3D printers themselves have become faster and more precise, delivering high-quality objects with less post-processing.

The integration of artificial intelligence and automation in production processes has enabled more efficient order management, cost reduction, and real-time optimization of printing parameters.

Moreover, collaborative platforms allow users to easily create and share custom designs, facilitating on-demand production for a wide variety of applications.

The Democratization of Access to 3D Printing

The democratization of access to 3D printing has accelerated thanks to the decline in prices of printers and materials, making this technology more accessible to individuals and small businesses. Online platforms now allow anyone to design, customize, and order 3D printed objects without requiring technical expertise or investment in expensive equipment.

Furthermore, the emergence of local workshops and on-demand services offers a practical alternative for those wishing to use this technology without owning a printer. This evolution facilitates the creation of prototypes, the production of small series, and even the customization of products for a growing number of consumers, while promoting the democratization of innovation and custom manufacturing.

New Economic Opportunities Offered by On-Demand 3D Printing

On-demand 3D printing opens up new economic opportunities by enabling the creation of flexible and customized business models. On one hand, it facilitates the rise of new commercial models, particularly through collaborative platforms where designers can sell their creations directly to consumers without investing in mass production.

On the other hand, the ability to produce on demand allows businesses to reduce storage costs and inventory management, while offering more personalized products, attracting new market segments. On-demand 3D printing also supports the circular economy by enabling the recycling or repair of objects, thus reducing waste and the need for raw materials.

Finally, it offers new possibilities for innovation in sectors such as fashion, healthcare, and automotive, where the rapid production of prototypes and unique parts meets specific needs, encouraging the emergence of previously inaccessible economic niches.

Conclusion: On-Demand 3D Printing

On-demand 3D printing represents a true revolution in the world of production and consumption. By offering advanced personalization, cost reduction, shorter manufacturing times, and unprecedented flexibility, it opens up exciting opportunities across many sectors—from industry and medicine to fashion and architecture.

While technical and regulatory challenges remain, advancements in materials, printing speed, and the accessibility of the technology point to a future where custom manufacturing becomes the standard. Thanks to its ecological, economic, and creative advantages, on-demand 3D printing is set to transform the way we design and produce, while meeting the needs of a world increasingly focused on personalization and sustainability.

Picture by Freepik.

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.

Our other 3D printing tutorials:

The history of 3D printing

Would you like to know more about the history of 3D printing to discover how…

Rapid 3D Printing

Are you wondering about rapid 3D printing and its production capacity? At Imprimy, we are…

The layer height in 3D printing

Would you like to discover everything you need to know about layer height in 3D…