Are you wondering about translucent 3D printing and how to achieve effective results? At Imprimy, we are here to answer all your questions.

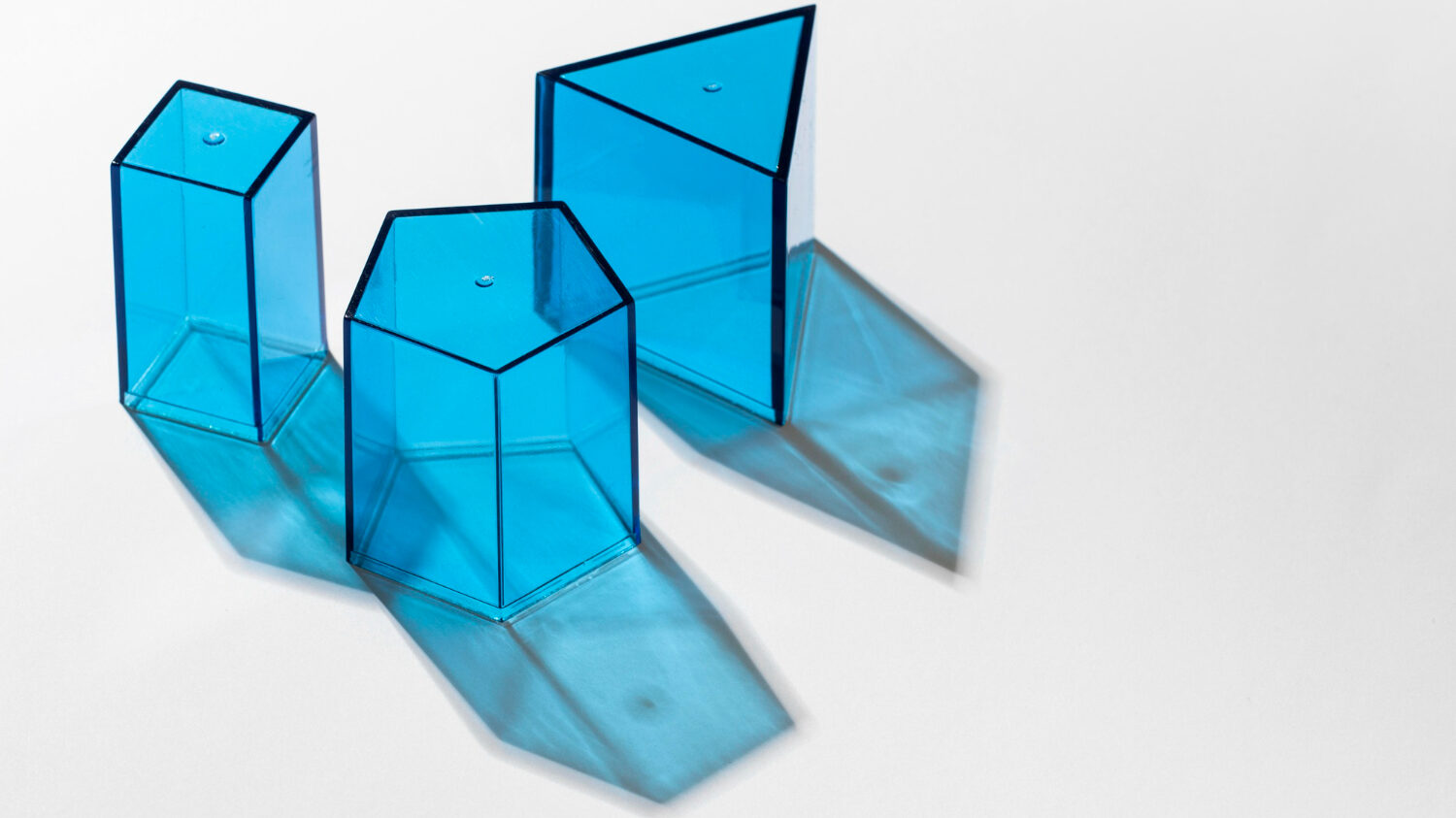

Translucent 3D printing allows you to create partially transparent objects using special materials such as photopolymer resins or certain PLA filaments, ideal for aesthetic or technical applications.

What is translucency in 3D printing?

Translucency in 3D printing refers to the ability of a printed object to allow light to pass through in a diffused manner, without being completely transparent. This depends on the material used, the wall thickness, and the print quality.

The difference between transparent, translucent, and opaque in 3D printing

In the field of 3D printing, it is essential to distinguish between the concepts of transparent, translucent, and opaque in order to choose the right materials and achieve the desired visual effect. A transparent object allows light to pass through clearly, enabling one to see through it distinctly, like a window; in 3D printing, this is difficult to achieve without intensive post-processing. A translucent object diffuses light without allowing clear vision through it: it lets light pass while blurring shapes, ideal for creating soft lighting effects or lamps.

Finally, an opaque object does not let any light pass through, completely blocking visibility. This is the case for most standard prints using materials like PLA or ABS. These three levels of transparency depend on the material, wall thickness, printing settings, and post-printing finishes.

Materials used for translucent effect

To achieve a translucent effect in 3D printing, several specific materials are available, each with its own characteristics.

- Translucent PLA, also called “ice” or “crystal” PLA, is very popular for its ease of printing and light diffusion effect, though it may slightly yellow over time.

- Transparent PETG is an excellent balance between strength and translucency: more durable than PLA, it allows for better light transmission, especially with thin walls.

- For more precise and smooth results, especially in the artistic or medical fields, SLA/DLP translucent resins (such as clear or amber resins) offer superior print quality and a very fine finish, ideal for post-processing (sanding, polishing, varnishing).

- There are also special filaments based on polycarbonate or transparent nylon, but their printing requires more advanced machines and precise settings.

The choice of translucent material depends on the desired balance between ease of printing, visual appearance, and mechanical strength.

Properties influencing the translucency of 3D prints

The translucency of a 3D print is influenced not only by the material but also by a range of physical and technical properties that affect how light passes through the object. One of the most important factors is the wall thickness: the thinner the walls, the more light can pass through, making the piece more translucent.

Next, printing settings play a key role: a low layer height (e.g., 0.1 mm) provides a smoother surface, reducing the light diffusion caused by layer lines. Similarly, a low or absent infill encourages uniform light diffusion, while a dense infill creates more opaque areas. The extrusion temperature also affects layer fusion: a temperature that is too low leaves micro-gaps that hinder translucency.

Finally, post-processing is crucial: sanding, polishing, and sometimes applying a clear varnish or resin help smooth the surface and significantly improve the object’s ability to diffuse or transmit light.

Techniques for successful translucent printing

To achieve a successful translucent 3D print, you should use translucent materials, set a fine layer height, minimize printing defects, and perform post-processing to enhance the transparency of the final object.

Choosing the right filament or resin for your translucent 3D prints

Choosing the right filament or resin is crucial to achieving a high-quality translucent 3D print. For FDM printers, translucent PLA filaments are the easiest to use: they are simple to print and offer a good light diffusion, making them perfect for decorative objects. If you’re looking for more strength while maintaining a light effect, transparent PETG is an excellent option: it provides better durability and light transmission, especially on thin walls. Transparent polycarbonates or PMMA (acrylic) offer translucency closer to glass, but they require high temperatures and a well-calibrated printer.

For resin printers, transparent SLA/DLP resins (often called clear or amber) provide an extremely fine and smooth finish, ideal for detailed or technical parts. It’s essential to choose high-quality materials to avoid impurities or micro-bubbles that can affect translucency. Opt for well-known brands and check user reviews to ensure good light rendering and reliable printing results.

Key settings for your 3D printer

To achieve a high-quality translucent 3D print, the settings of your 3D printer are just as important as the choice of material. First, a low layer height (0.1 mm or less) helps reduce visible striation lines and optimizes the diffusion of light through the piece.

Next, it’s recommended to decrease the print speed to ensure better layer fusion, which limits the presence of micro-gaps that can affect translucency. The extrusion temperature should be slightly higher than usual to ensure better layer adhesion and a smoother finish; however, be careful not to exceed the point where the filament starts to degrade.

The infill should be low or even absent if strength is not a priority: a hollow or partially filled object allows light to pass through more easily. Similarly, reduce the number of internal walls and top/bottom layers to maximize translucency.

Finally, strategically orient the part to minimize shadowed areas and take advantage of the natural light diffusion along the direction of the layers.

Finishes to enhance the translucency of your 3D prints

Post-printing finishes are essential to enhance the translucent effect of your 3D prints and maximize the light transmission or diffusion. The first key step is sanding: start with a medium grit (200–400) to smooth out the print lines, then gradually move to very fine grits (up to 2000 or more) to achieve a soft, satin-like finish. For resin prints, an isopropyl alcohol (IPA) bath helps remove sticky residues and smooths the surface.

Next, manual polishing or using specialized polishing pastes restores shine and enhances translucency. Applying a clear varnish (acrylic or polyurethane spray) can also improve light diffusion while protecting the piece. For a “crystal” effect, some people use epoxy resin, applied in a thin layer over the surface, which fills micro-defects and creates an ultra-smooth finish.

These steps, although time-consuming, transform a raw print into a true light-emitting object, with a finish similar to glass or molded plastic.

What are the different applications of translucent 3D printing?

The applications of translucent 3D printing include creating visual prototypes, custom lighting, transparent mechanical parts for internal observation, decorative objects, medical implants to simulate anatomical structures, and design elements for architecture or fashion.

Translucent 3D printing in design and decoration

Translucent 3D printing opens up new creative possibilities in the world of design and decoration, playing with light, shapes, and textures. With materials capable of diffusing light, it’s possible to create custom lamps, tealight holders, lampshades, or backlit furniture elements that transform the atmosphere of a space.

Designers use translucency to create effects like mist, frosted glass, or frost, giving objects a soft and poetic aesthetic. 3D printing also allows the creation of complex, organic patterns that, when illuminated, reveal fascinating shadow play. By adjusting the thicknesses, surface textures, and layer orientation, the way light is absorbed or diffused can be tailored, creating a completely unique result.

Translucent 3D printing in prototyping and engineering

In the field of prototyping and engineering, translucent 3D printing plays a strategic role by enabling the internal visualization of complex parts. It is particularly useful for designing and testing fluidic components, flow channels, or internal chambers, where it is crucial to observe how a liquid, air, or light beam moves inside the structure.

Translucent materials also allow for the detection of potential bubbles, cracks, or design defects without having to cut open the part. Furthermore, for presentations or functional testing, a translucent part provides a visual insight that is very informative while maintaining satisfactory mechanical properties, especially with technical SLA resins or transparent PETG.

This technology is also used to create semi-transparent electronic enclosures, optical sensors, or molds to test before production. Translucent 3D printing thus becomes a powerful tool to accelerate product development, reduce physical iterations, and visually validate internal features, all while keeping costs under control.

Translucent 3D printing in art and jewelry creation

In the world of art and jewelry creation, translucent 3D printing opens up a fascinating realm of expression where light becomes a true creative material. Artists use this translucency to play with shadows, reflections, and partial transparency, giving birth to ethereal, almost living sculptures that interact with their luminous environment.

In jewelry design, translucent SLA resins allow for the creation of light, refined, and organic pieces that subtly capture and diffuse light, creating a soft shine or frosted glass effect. This technique also enables gradient effects, finely engraved textures, and structures that are impossible to achieve with traditional casting, while ensuring extreme detail precision.

Translucent printing can also be combined with opaque or metallic materials to create striking visual contrasts, enhancing the artistic dimension of the pieces. It allows creators to explore new forms of visual storytelling, blending technology, poetry, and light.

What are the limitations and perspectives of translucent 3D printing?

The limitations of translucent 3D printing include potentially low mechanical strength, limited precision in fine details, and aesthetic defects such as air bubbles. However, the perspectives are promising with the continuous improvement of materials, more advanced finishing techniques, and innovative applications in fields such as medicine, lighting, and design.

Current limitations of translucent 3D printing

Despite its many advantages, translucent 3D printing still faces several technical limitations that hinder its widespread use in some demanding applications. First, achieving perfect transparency, comparable to glass or molded plastic, remains very difficult without heavy post-processing (sanding, polishing, resin coating), which requires time and expertise. Additionally, many translucent materials available for FDM printing, such as PLA or PETG, have limited mechanical or thermal strength, making them unsuitable for intense industrial use.

On the resin side, while optical quality is better, these materials can be fragile or sensitive to UV light, leading to yellowing or loss of clarity over time. Furthermore, printing imperfections, such as bubbles, layer lines, or dust, quickly affect the desired visual effect. Finally, most consumer-grade 3D printers are not optimized to produce ultra-translucent objects without precise adjustments, limiting the reproducibility of results. These technical challenges show that, despite its potential, translucent 3D printing remains a hybrid discipline, straddling art, prototyping, and experimentation.

Upcoming innovations in translucent 3D printing

The upcoming innovations in translucent 3D printing promise to push the current boundaries and pave the way for more ambitious applications. One of the most anticipated advances concerns the development of new translucent materials with better optical clarity, greater mechanical strength, and long-term stability (particularly against UV exposure).

Manufacturers are already working on high-transparency resins, close to glass, and hybrid filaments that combine technical and aesthetic properties. On the hardware side, next-generation 3D printers, particularly in resin (SLA/DLP/LCD), are integrating more precise and better-calibrated systems to ensure smoother and more uniform prints, reducing surface defects.

We are also seeing the emergence of automated post-processing techniques: steam polishing stations, optimized UV treatments, and robotic varnishing, which enhance translucency without manual intervention.

Finally, multi-material and multi-color technologies allow for the combination of translucent, opaque, or textured areas within the same part, opening the door to more functional and artistic creations. These technical advancements aim to make translucent 3D printing more accessible, faster, and more efficient, benefiting both design and industry.

Conclusion: Translucent 3D Printing

In conclusion, translucent 3D printing represents an exciting convergence of technology, aesthetics, and functionality, offering creators, engineers, and designers a powerful tool to explore light as a material. Whether it’s for creating subtle decorative objects, smartly designed technical prototypes, or illuminated artistic works, this technique allows for advanced customization and unique renders, at the crossroads of transparency and creativity.

Although it still presents certain limitations, particularly in terms of perfect clarity or material strength, upcoming innovations promise a bright future, where translucency will not only be mastered but also used as a true visual language. Accessible, modular, and constantly evolving, translucent 3D printing invites everyone to experiment, innovate, and shape light.

Picture by Freepik.

The articles published on Imprimy.com are for informational purposes only. They are intended to provide general advice and information related to 3D printing. Imprimy.com cannot be held responsible for the results obtained or the consequences arising from the application of the shared information. We recommend always checking the specific instructions for your hardware and materials before use.